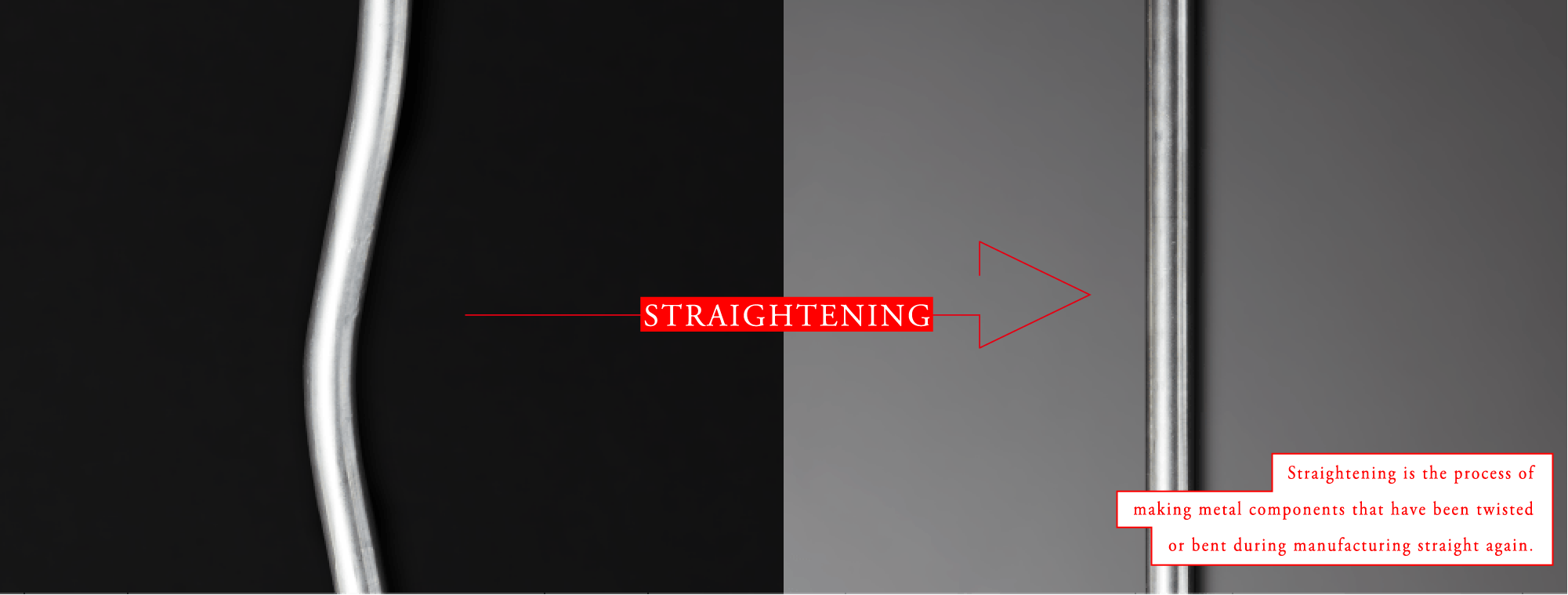

We accept straightening order our competitors find difficult to complete

Don’t’ give up! Your distorted products can be repaired. We have solved many problems that makers or vendors were unable to handle. Simply call or email us today to see what we can do for you.

Our straightening services

HIGH-precision can be achieved

ANY shapes can be straighten

ANY materials can be straighten

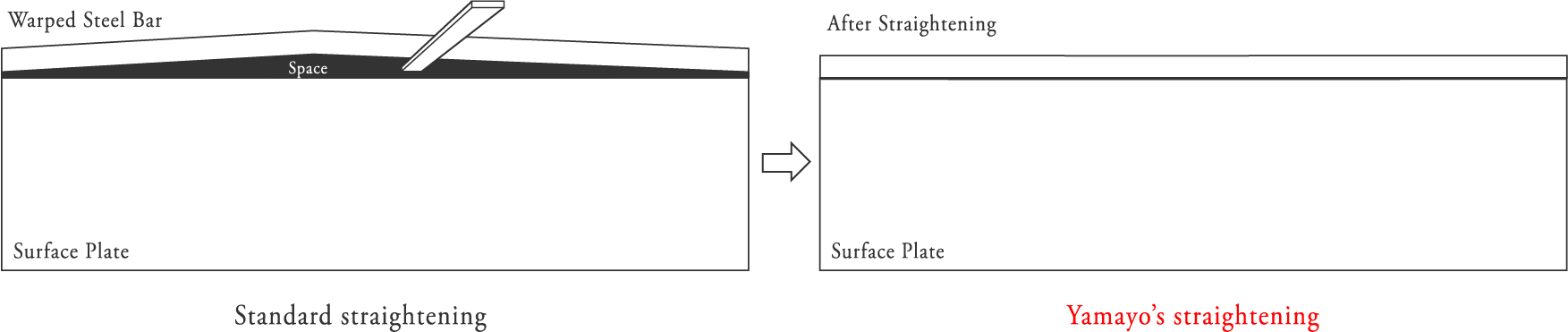

PRECISION

In general, curves after straightening services are 3mm per 1 meter. Meanwhile our straightening refines products to a straightness of 0.5–0.05mm or less per 4 meters.

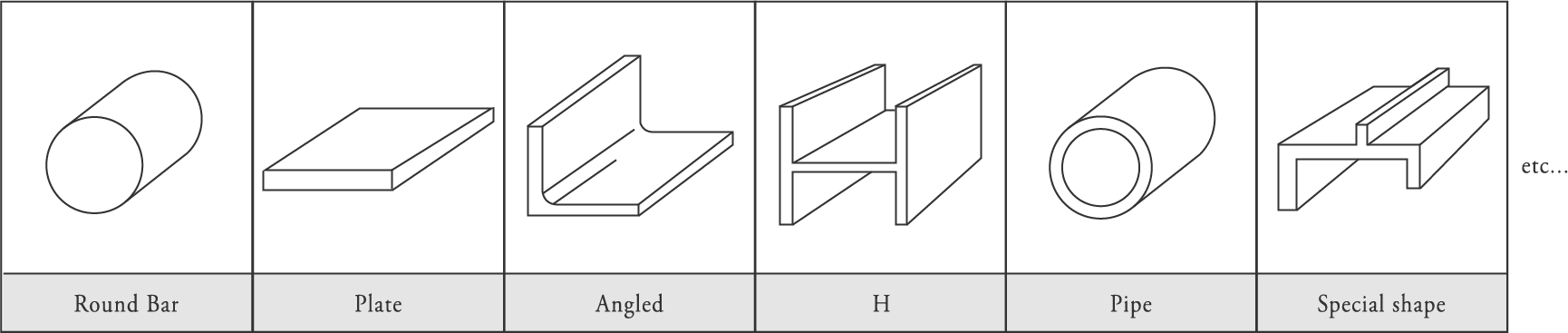

SHAPE

Whether the material is round, squared off, a plate, or a special form, we can straighten it without any difficulties.

etc...

MATERIAL

| Material | HV |

|---|---|

| Beryllium Copper | 350-400 |

| SUS630 | 375 |

| Inconel Alloy | 150-280 |

| S45C | 201-269 |

| Titanium Alloy | 110-150 |

| Aluminium | 183 |

| Gold・Silver | 22/25 |

Straightening Available

Apart from the left table, we handle various materials. Straightening of titanium, duralumin, and other difficult-to-handle materials are our strengths in technology.

Straightening Available

Why manual straightening?

Machine straightening (roll straightening, plate leveler, etc.) is often troublesome and applicable under only limited conditions. On the contrary, manual straightening achieves a high level of precision regardless of the material types if operated by experienced engineers. Although there is a few companies specialized in manual straightening in Japan, we are one and only who can straighten any shapes or materials and can satisfy extreme specifications.

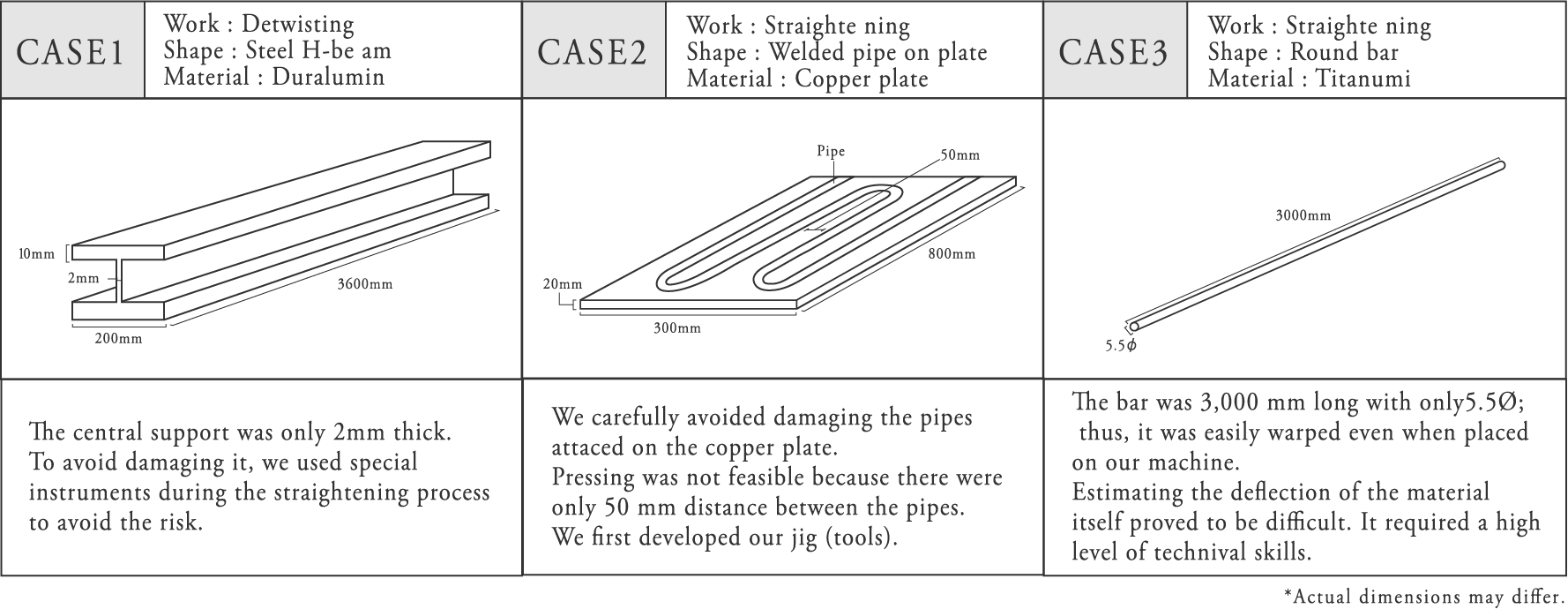

Our Works

Here are just a few examples of projects that required high skill

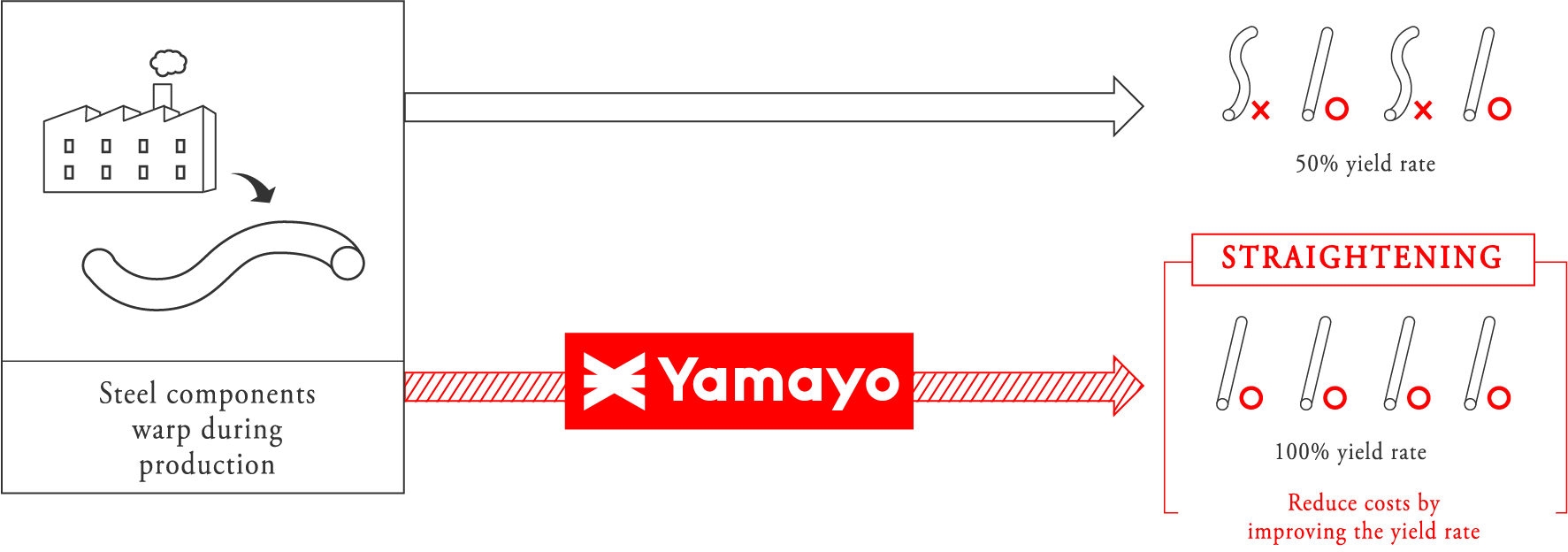

The merit of straightening: Cost reduction

Aiming to be the number 1 straightening specialist

Manual straightening has a high degree of freedom; it is very convenient, but the precision substantially reflects the proficiency of the craftsman who operates the machine. Our craftsmen seek straightness and flatness without compromises. To handle high-quality steel products, they must have profound knowledge over metal components, and then press at the proper position with the proper pressure. The training is not easy, but Yamayo has proud craftsmen who are believed to be the best in Japan. We want to offer all our clients the best quality and the best available percentage. With this in mind, everyone at Yamayo works and trains hard for our clients satisfaction.